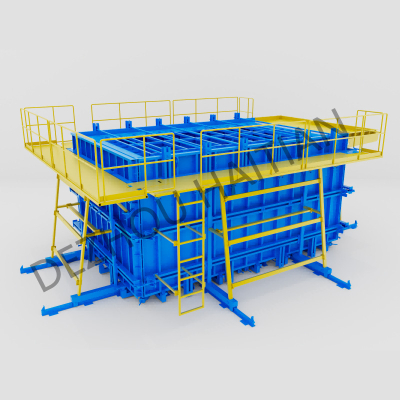

Concrete Beam And Column Mold

1、The prestressed beam and column mould is designed for the forming of precast concrete beams and columns.

2、It is widely used in bridge construction, building projects, and prefabricated structures. 3、Made of high-strength steel plates, the mould ensures

4、structural stability, easy installation and dismantling, precise dimensions, and a smooth concrete surface finish. Customized designs are available to meet various specifications and project requirements.

In the field of construction, high-quality molds are crucial for ensuring structural quality and efficiency. Concrete beam and column molds, with their various advantages, have become the preferred choice for numerous projects. Firstly, the concrete beam and column molds are made of high-strength steel, which has strong resistance to deformation. They can be reused for up to several dozen times, significantly reducing the cost of molds per single construction. This helps save expenses for the project. Secondly, the assembly accuracy of this mold is extremely high. After assembly, the gaps are tight, effectively preventing leakage during concrete pouring, resulting in a smooth and flat surface for the formed beams and columns, reducing the need for subsequent grinding processes and improving construction efficiency.

Furthermore, the design of the concrete beam and column molds takes into account the convenience of construction. The accessories are highly versatile, and installation and disassembly do not require complex equipment. Ordinary workers can operate them after simple training, shortening the mold turnover time. At the same time, for different projects' requirements for beam and column dimensions, the concrete beam and column molds can be flexibly customized. Whether it is an irregular section or a standard specification, they can precisely match the design requirements and meet diverse construction scenarios. Additionally, the mold surface is specially treated for rust prevention, maintaining good performance even in humid construction environments, extending the service life and further highlighting the dual advantages of the concrete beam and column molds in terms of practicality and economy.

High-quality material: Ultra-durable control panel

The upgrade in material has endowed the concrete beam and column molds with extraordinary durability, which is their primary feature. The molds are made of high-strength alloy steel combined with a wear-resistant coating composite process, and their resistance to bending and deformation far exceeds that of ordinary steel molds. In high-intensity construction scenarios involving repeated pouring and vibration, the concrete beam and column molds can be used multiple times. Compared to traditional wooden or ordinary steel molds, their service life is significantly extended, and the cost per mold for a single construction is significantly reduced. This is particularly suitable for large-scale construction projects such as building complexes and bridges, which can greatly reduce the frequency of mold replacement and the investment in mold procurement.

Precise craftsmanship: Excellent shaping ensures quality

The outstanding forming effect achieved through precise craftsmanship further highlights the core value of the concrete beam and column molds. The molds are manufactured using CNC processing technology, featuring seamless interface connections with extremely small gaps. After assembly, a sealed pouring space is formed, effectively eliminating the problems of leakage and mold displacement from the very beginning. The surfaces of the beams and columns after pouring are smooth and flat, requiring no additional plastering or sanding processes. They directly meet the standards of plain concrete decoration. This advantage not only reduces the labor and material consumption in the subsequent decoration process but also avoids the problem of uneven structural force caused by surface defects, enhancing the stability of the beam and column load-bearing capacity.

Designing for humanity: Simplified operation boosts efficiency

The humanized design enables the concrete beam and column molds to have extremely high construction convenience. The mold components adopt standardized modular design, resulting in a lighter overall weight. During installation, no large-scale lifting equipment is required, and a small number of construction workers, after simple training, can complete the assembly process. In the disassembly stage, a snap-fit quick-release structure is used, which does not rely on heavy tools such as crowbars and hammers. This not only reduces the labor intensity of the workers but also avoids damage to the molds and formed beams and columns during disassembly, significantly shortening the mold turnover cycle and effectively accelerating the overall construction progress.

Flexible adaptation: Customized weather-resistant expansion scenarios

The flexible customization capability and weather-resistant design enable the concrete beam and column molds to adapt to various construction needs. For special designs such as irregular beams and columns in industrial plants, or variable-section beams and columns in bridges, the molds can achieve full parameter customization of section dimensions, length, and reserved holes. The customization cycle is short, and it can precisely match the special construction requirements. At the same time, the surface of the molds is professionally treated for rust prevention. During construction in damp environments such as basements or rainy seasons, the rust coating can effectively prevent water vapor erosion, extend the service life, and can adapt to different regions and different working conditions of construction requirements.

In conclusion, the concrete beam and column molds achieve cost reduction through high-quality materials, enhance quality through precise craftsmanship, increase efficiency through convenient design, and expand application scenarios through flexible adaptation. Their diverse advantages empower the entire construction process, providing efficient and reliable solutions for construction projects. They are important equipment for promoting the industrialization upgrade of construction projects.